|

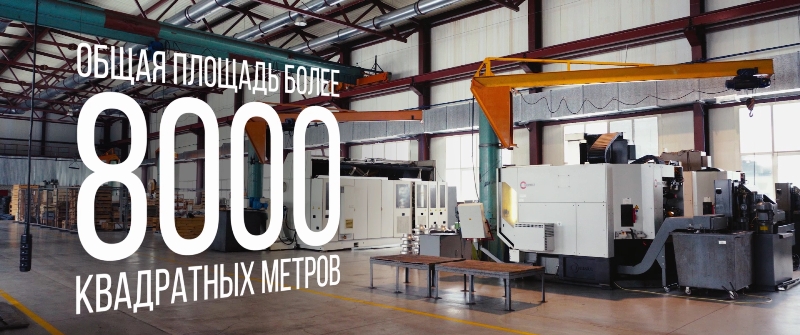

The SKBT manufacturing facilities include two engineering and technical buildings (3,800 m2 and 800 m2), two machining departments (4,500 m2 and 4,000 m2), the foundry laboratory (900 m2), and the testing station (400 m2). The total enterprise area is over 27,000 m2. Now, the investment programme is in progress for purchasing new modern high-tech equipment, the number of equipment to be purchased is 30 pieces. With this equipment purchased, the enterprise will be capable to raise the output more than twofold, and to enter the world market, providing appropriate competition for leading foreign manufacturers of turbochargers and spare parts. |

The primary process equipment fleet comprises over 150 pieces now.

The equipment by groups is as follows:

1. Lathes and vertical boring mills: 39 pieces, including those with the NC: 8.

2. Drilling and coordinate machines: 20 pieces, including those with the NC: 2.

3. Grinding and polishing machines: 24 pieces, including those with the NC: 3.

4. Gear-making machines: 4.

5. Milling and boring machines: 16, including those with the NC: 4.

6. Broaching machines: 3.

7. Slitting machine tools: 6.

8. Presses: 3.

9. Bending machines: 3.

10. Balancing machines: 3, including those with the NC: 3.

11. Welding machines: 6.

12. Woodworking machines: 4.

13. Thermal treatment equipment: 8.

14. Foundry equipment: 9.

The SKBT LLC equipment and personnel skills are appropriate to carry out the following kinds of works:

1. Lost-wax vacuum precision casting of heat-resistant alloys (gas turbine blades, turbine wheels with the diameter up to 300 mm).

2. Air-melting precision steel casting for making parts weighting up to 15 kg (nozzle diaphragm rims, nozzle blades, sectors, gas channels, gas-collecting housings, impellers, flanges, tee joints, nipples).

3. Chill casting of aluminium alloys using centrifugal method for making parts weighting up to 50 kg (compressor wheels, diffusors, guide apparatus).

4. Casting in sand moulds using the pattern equipment for making aluminium-alloy parts weighting up to 100 kg.

5. Bulk heat treatment in chamber furnaces and shaft furnaces, high-frequency current hardening, cementation.

6. Carbon dioxide shielded semiautomatic welding.

7. Manual arc welding.

8. Argon arc welding.

9. Friction welding of difficult-to-weld dissimilar steels and alloys with the welded joint diameter 25…60 mm (rotor shafts and turbine wheels, milling cutters, core drills, reamers, drills).

10. Machining of geometrically-complex surfaces using the creep feed grinding method.

11. Five-axis milling of sculpted surfaces for parts made of aluminium alloys and steel alloys (compressor wheels, impellers, moulds, dies, case-type parts of compressors, turbines, gates, reduction gears).

12. Milling of flat profile surfaces.

13. Machining of lathe-group parts having any level of complexity using the machining centres, with single-setup milling, drilling, thread-cutting, thread-rolling operations and part superfinishing (rotor shafts, bearing housings, crankshafts, camshafts, bushings, cowls, pistons).

14. Machining of case-type parts using the turning-and-boring lathes, with the diameter up to 2,000 mm and height up to 1,500 mm (casings for turbines, compressors, reduction gears, flanges, transportation wheels and hoisting mechanisms).

15. Machining of contoured surfaces on solids of revolution, with the diameter up to 650 mm.

16. Machining of elements for toothed and splined joints using the milling, slotting and broaching methods.

17. Coordinate boring, coordinate milling and coordinate drilling operations for machining of parts, up to 100 kg.

18. Balancing of turned parts, up to 150 kg (shafts, rotors etc.).

19. Non-destructive inspection: magnetic-particle, ultrasonic and radiographic methods.

20. Measuring geometrically-complex surfaces using the ZEISS prizmo navigator inspection and measuring machine.

SKBT LLC is capable to provide services in machining of cylindrical-shape parts made of various alloys of ordinary and high-strength grades.

Manufacturing accuracy: up to 0.03 mm.

Maximum weight: 5 000 kg.

Maximum overall dimensions: Ø 2 500 mm * 1 500 mm.

We are ready to consider, on a contractual basis, the possibility of manufacturing in accordance with your orders, as provided by our process capabilities and personnel skills.

You can use the details listed in the Contacts section to send your request.